Available for Import

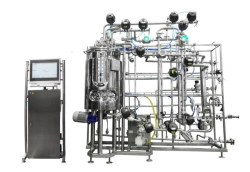

Available for ImportAutomated Ion-Plasma Coating System MAP-3 for Industrial Applications

Manufacturer:National Research Center "Kurchatov Institute" - VIAM

Price:Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

The unit is designed for application of heat-resistant, corrosion-resistant, erosion-resistant, wear-resistant coatings on turbine and compressor blades of GTE, hard coatings from metal compounds on cutting tools and parts of GTE, including assisted deposition, and also allows to carry out ion etching and ion saturation of the treated surface with metal ions.

Specifications

Number of pieces to be processed simultaneously

12...24 pcs

Speed of coating condensation on the substrate, not more, ?m/min

0.35

Chamber pressure during product cleaning with gas-discharge ion source

0.04...0.053

Pressure in the chamber during coating: metallic

0.0266...0.00665

Pressure in the chamber during coating: cermet coating

0.266...0.1064

Pumping duration up to working pressure of 0.0266 Pa, not more than

60

Cooling water flow rate

5...8

Installed capacity

95 kW

Overall dimensions of the installation (dxhxv), not more than

4700 x 2500 x 2850 mm

Maximum dimensions of the spraying area on the workpiece, not more, (diameter × height)

125 × 200 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination) Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Cylindrical Conical Fermentation Tank CCT

View Details

Bitumen Emulsion Preparation Unit Bastion EU-5

View Details

Hydraulic Test Installation for Cylinder Heads UГ1400

View Details

Automated Ion-Plasma Coating System MAP-2M

View Details

Autoclaves for Vulcanization and Composite Polymerization, Models AV, AP, AT, and AU Systems

View Details

Biorus® Pilot Fermenter for Aerobic and Anaerobic Cultivation

View Details

Biotechno Filtration Systems - Polymer Membrane Based

View Details

Automated Ion-Plasma Coating System MAP-5

View Details

Friction Welding Machine PST-20T for Drill Pipe Production

View Details

Hot Washing Bath Model VGP-1 for Part Neutralization

View Details

Biotechno Fermenters for Cell Cultures (5 to 3000 liters)

View Details

Electric Oil Bath for Liquid Cooling - Model VM

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions