Available for Import

Available for Import

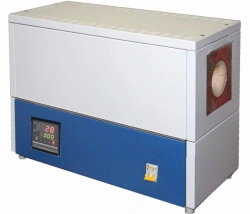

Infrared Convection Oven AПИК 2.2 ART for Small Batch Production

Manufacturer:

VEGA-PRO LLC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

convection-infrared table-top chamber furnace for low-volume and pilot production. With the ability to work on lead-free technology and soldering in an inert environment;

45 programmable soldering and drying profiles;

PC connection for soldering process documentation and software updates;

working area size up to 300×310 mm, height of components up to 30 mm;

220 V single-phase power supply;

compact design, improved layout;

built-in Wi-Fi module for external control from Andriod tablet.

45 programmable soldering and drying profiles;

PC connection for soldering process documentation and software updates;

working area size up to 300×310 mm, height of components up to 30 mm;

220 V single-phase power supply;

compact design, improved layout;

built-in Wi-Fi module for external control from Andriod tablet.

Specifications

Maximum overall dimensions of the printed circuit board

300×310 mm

Number of work programs (Standard/ Accelerated/Drying)

15/15/15

Heating temperature

260 °C

Temperature setting step

1 °C

Heating rate

10...30 °C/min

Heating speed setting step

1 °C/min

Drying time

0...60 min

Flux activation time

0...300 sec

Solder melting time

0...99 sec

Range over Wi-Fi wireless interface, not less than

3 m

Supply mains voltage

220 V

Frequency

SBVVBG

Current

14 A

Width

445 mm

Depth

490 mm

Height

390 mm

Weight

25 kg

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

SVG Heating Bath for Melting Lead, Tin, and Zinc

View Details

Salt Bath Furnace for Heating Details - SVC Model

View Details

Vertical Shaft Furnace LOIP LF-70/13-G1

View Details

Vacuum Station for Electro-Vacuum Processing EVO-22/4-250

View Details

Tubular Furnace LOIP LF-50/500-1200 for Heat Treatment

View Details

High-Temperature Furnace VTP 1800-1

View Details

Laboratory Muffel Furnace LF-7/13-V2

View Details

Laboratory Muffler Furnace LF-15/11-V1

View Details

Oil Bath Heating Oven SVM for Component Heating

View Details

Vacuum Diffusion Furnace D-6.6.3,5-9,5SS-RV

View Details

Laboratory Muffle Furnace LF-15/13-V1 for Ashing and Heating

View Details

Laboratory Muffle Furnace for Sample Preparation LF-5/13-G1

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions